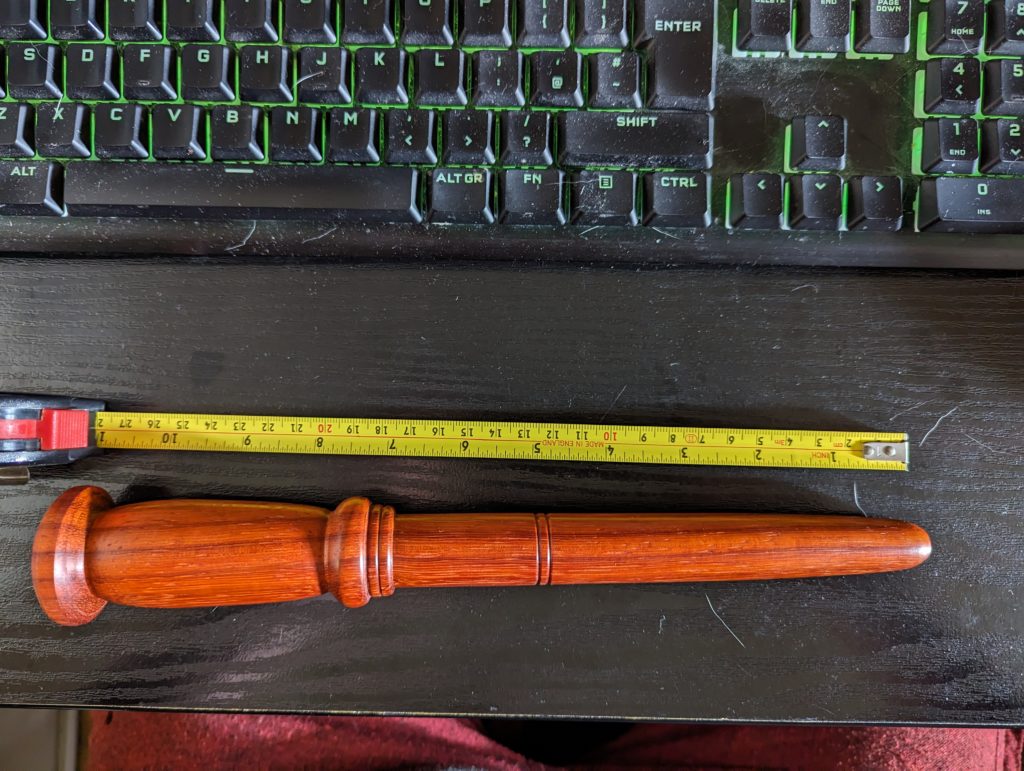

Well, this is actually my second lathe. My first one was the Parkside lathe from Lidl, which I bought probably two or three weeks ago. I’ve used it (the Parkside one) to turn two pieces of wood (other than some very quick tests). I made a bowl out of sycamore and a cup / goblet / thing out of apple wood (from a tree we cut down in our garden).

I had read bad things about the Parkside lathe, but I really wanted to give turning a go, and as they re-appeared in the middle of Lidl I purchased one in a moment of weakness.

I had read bad things about the Parkside lathe, but I really wanted to give turning a go, and as they re-appeared in the middle of Lidl I purchased one in a moment of weakness.

Super easy to set up, made mostly of plastic and aluminium, the lathe sits nicely on a bench. But it’s flimsy. The spindle wiggles, the tool rest doesn’t lock fully, the tailstock actually lifts up from the lathe ‘bed’ (I use that term loosely) if you apply it hard enough to keep your piece in place.

But, it does allow you to turn wood, even someone like me who’s never turned anything his life. I made the bowl and the other thing (chalice?) and it was only mildly frustrating and painful. But, by the time I’d finished the second piece, the lathe was even flimsier. The wobble on the spindle was worse, the tool rest is chipped and dented and no longer locks, and the tail stock is as useful as a piece of wet fish. It was clear I was doing stuff it was never intended to be useful for (which begs the question, what was it intended to be used for).

Anyway, I’d been watching Facebook market place for months for various second hand DIY items (more blog posts coming about all that stuff I suspect) and yesterday I spotted a bargain. A Record Power CL2 lathe, for a really good price, not too far away and in good working order. I collected it today.

Fuck me it’s heavy. I mean, it didn’t look that big in the Facebook marketplace photo. But it’s heavy. The two metal bars which form the bed are heavy. The motor and spindle are very heavy. I really should not have been lifting that onto the bench on my own. It came with loads of accessories including an unused four jaw chuck, which I’m super excited about.

Fuck me it’s heavy. I mean, it didn’t look that big in the Facebook marketplace photo. But it’s heavy. The two metal bars which form the bed are heavy. The motor and spindle are very heavy. I really should not have been lifting that onto the bench on my own. It came with loads of accessories including an unused four jaw chuck, which I’m super excited about.

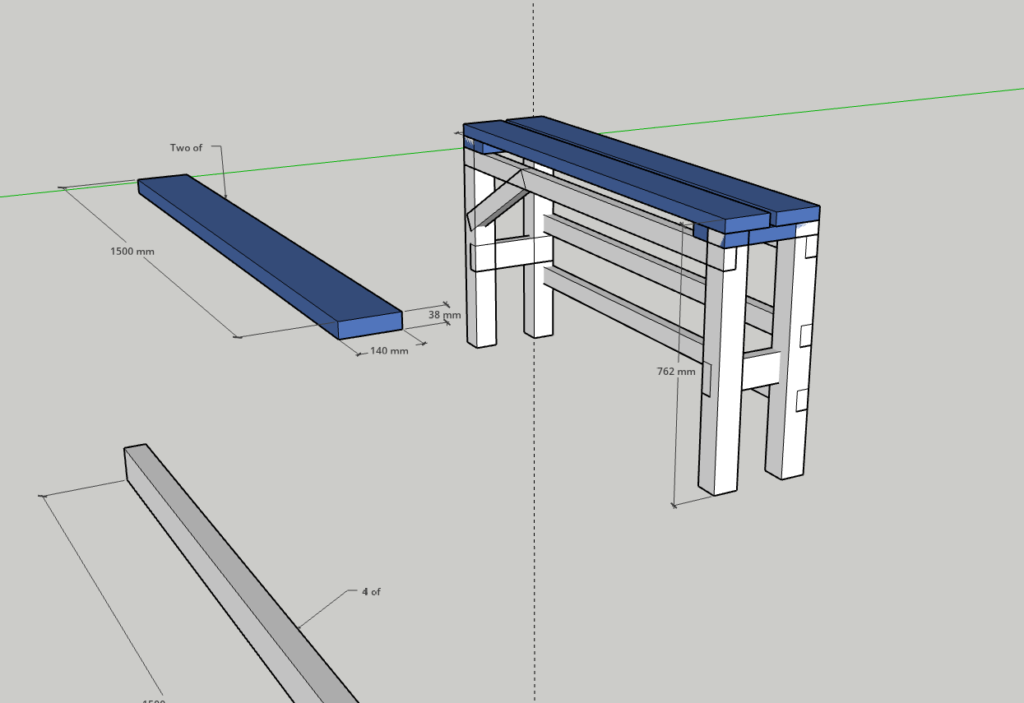

Now I just need to build a stand for it (it can’t stay on the bench, it’s too high for one thing), and then enlist the help of someone to move it (not making that mistake again).

I am excited to give it a whirl – the two things I’ve made were hard, but I don’t know if that was technique, the lathe or the tools (or all three). It can’t be the lathe next time I make something, so we’ll hopefully see if it’s tools, technique or both!

I had read bad things about the Parkside lathe, but I really wanted to give turning a go, and as they re-appeared in the middle of Lidl I purchased one in a moment of weakness.

I had read bad things about the Parkside lathe, but I really wanted to give turning a go, and as they re-appeared in the middle of Lidl I purchased one in a moment of weakness. Fuck me it’s heavy. I mean, it didn’t look that big in the Facebook marketplace photo. But it’s heavy. The two metal bars which form the bed are heavy. The motor and spindle are very heavy. I really should not have been lifting that onto the bench on my own. It came with loads of accessories including an unused four jaw chuck, which I’m super excited about.

Fuck me it’s heavy. I mean, it didn’t look that big in the Facebook marketplace photo. But it’s heavy. The two metal bars which form the bed are heavy. The motor and spindle are very heavy. I really should not have been lifting that onto the bench on my own. It came with loads of accessories including an unused four jaw chuck, which I’m super excited about.